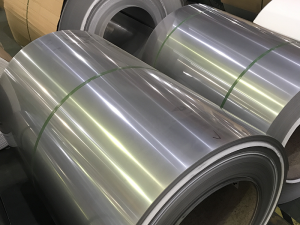

410S Ikhoyili yeNsimbi engatyiwayo

Inkcazo

Iinkcukacha:

1.Umgangatho: ASTM A240, JIS G4304, EN10088

2. IBakala: 200series&300series&400series

3. Ukutyeba: 0.03mm - 6.0mm

4. Ububanzi: 8mm-600mm

5. Ubude: njengesicelo sabathengi

6. Umphezulu: 2D, 2B, BA, Mirror igqityiwe, N04, Hair Line, Matt finish, 6K, 8K

7.Ubuchwephesha: ukubanda kutsalwa/kubanda kuqengqeleka/kushushu kuqengqeleka

Izixhobo:

| Uhlobo | IBanga | IBanga | Icandelo leMichiza % | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Okunye | |||

| I-Austenitic | 201 | SUS201 | ≤0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 | - |

| 202 | SUS202 | ≤0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ≤0.060 | ≤0.030 | ≤1.00 | - | ≤0.25 | - | ||

| 301 | 1.4310 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | ≤0.10 | - | |

| 304 | 1.4301 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304L | 1.4307 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304H | 1.4948 | 0.04-0.10 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309 | 1.4828 | ≤0.20 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309S | * | ≤0.08 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 310 | 1.4842 | ≤0.25 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 310S | * | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 314 | 1.4841 | ≤0.25 | 23.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | 1.50-3.00 | - | - | - | |

| 316 | 1.4401 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316L | 1.4404 | ≤0.030 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316Ti | 1.4571 | ≤0.08 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | 0.1 | Ti5(C+N)~0.70 | |

| 317 | * | ≤0.08 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 317L | 1.4438 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 321 | 1.4541 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 321H | * | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 347 | 1.4550 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C% -1.10 | |

| 347H | 1.494 | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C% -1.10 | |

| I-Duplex | 2205 | S32205 | ≤0.03 | 22.0-23.0 | 4.5-6.5 | ≤2.00 | ≤0.030 | ≤0.020 | 3.0-3.5 | ≤1.00 | - | 0.14-0.20 | |

| 2507 | S32750 | ≤0.03 | 24.0-26.0 | 6.0-8.0 | ≤1.20 | ≤0.035 | ≤0.020 | 3.0-5.0 | ≤0.80 | 0.5 | 0.24-0.32 | ||

| Ferrite | 409 | S40900 | ≤0.03 | 10.50-11.70 | 0.5 | ≤1.00 | ≤0.040 | ≤0.020 | - | ≤1.00 | - | ≤0.030 | Ti6(C+N)~0.50 Nb:0.17 |

| 430 | 1Kr17 | ≤0.12 | 16.00-18.00 | - | ≤1.0 | ≤0.040 | ≤0.030 | - | ≤1.0 | - | - | - | |

| 444 | S44400 | ≤0.025 | 17.50-19.50 | 1 | ≤1.00 | ≤0.040 | ≤0.030 | 1.75-2.5 | ≤1.00 | - | 0.035 | Ti+Nb:0.2+4(C+N)~0.80 | |

| Martensite | 410 | 1Kr13 | 0.08-0.15 | 11.50-13.50 | 0.75 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 410S | * | ≤0.080 | 11.50-13.50 | 0.6 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420 | 2Kr13 | ≥0.15 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| PH | 630 | 17-4PH | ≤0.07 | 15.00-17.50 | 3.00-5.00 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | 3.00-5.00 | - | Nb 0.15-0.45 |

| 631 | 17-7PH | ≤0.09 | 16.00-18.00 | 6.50-7.50 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | ≤0.50 | - | Al 0.75-1.50 | |

| 632 | 15-5PH | ≤0.09 | 14.00-16.00 | 3.50-5.50 | ≤1.00 | ≤0.040 | ≤0.030 | 2.00-3.00 | ≤1.00 | 2.5-4.5 | - | Al 0.75-1.50 | |

Ulwazi olusisiseko

I-410s ye-Stainless Steel Coil, enokumelana nokugqwala okulungileyo kunye nokunyanzeliswa kwe-machinability, yinjongo eqhelekileyo yentsimbi kunye nesixhobo sokusika insimbi.I-410S luhlobo lwensimbi olunokuphucula ukuxhathisa kwe-corrosion kunye nokubunjwa kwe-410 steel.410S yintsimbi yamandla aphezulu anokuthi aphucule ngakumbi ukuxhathisa kwe-410 yensimbi.Isetyenziselwa iiblade ze turbine kunye neendawo zobushushu obuphezulu.

• Iinkcukacha: AISI 410s, ASTM 410s

• Ukugqiba: I-Ba surface, i-2b surface, i-No.1 (isikhumba esimhlophe), i-2D surface, i-No.4 (iqabaka), i-HL (umzobo wocingo), umphezulu we-8K unomgangatho obalaseleyo womphezulu

• Unyamezelo lweMill kubunzima kunye nokuthe tyaba kuyasebenza. Fowunela i-JM Steel ukuba ufuna ubungakanani obuthile okanye icala lengqolowa.

I-410S iteknoloji yobuchwephesha bomatshini

1D -- Umphezulu unemilo yegranular eyekayo, ekwabizwa ngokuba ngumphezulu wenkungu.

Itekhnoloji yokucutshungulwa: ukuqengqeleka okushushu + ukuqhotsa i-annealing shot + ukuqengqeleka okubandayo + ukunyuswa kwe-annealing.

2D - Umbala omhlophe okwesilivere kancinci.

Itekhnoloji yokucutshungulwa: ukuqengqeleka okushushu + ukuqhotsa i-annealing shot + ukuqengqeleka okubandayo + ukunyuswa kwe-annealing.

I-2B -- Isilivere emhlophe kunye neglosi engcono kunye nokuthe tyaba kunomphezulu we-2D.

Itekhnoloji yokucubungula: ukuqengqeleka okutshisayo + ukugoba i-annealing shot peening pickling + ukuqengqeleka okubandayo + ukucolwa kwe-anneal + nokucima nokuqengqeleka.

I-Ba - Iglosi yeglosi egqwesileyo, imbonakalo ephezulu, njengomgangatho wesipili.

Itekhnoloji yokucubungula: ukuqengqeleka okutshisayo + ukugoba ukudubula okukroliweyo + ukuqengqeleka okubandayo + ukucolwa kwe-anneal + ukupolisha komphezulu + ukucima nokuqengqeleka.

No.3 -- Iglosi elungileyo, umphezulu wenkozo orhabaxa.

Itekhnoloji yokucutshungulwa: ukupolisha kunye ne-teering rolling ye-2D okanye i-2B ene-100 ~ 120 imathiriyeli ye-abrasive (JIS R6002).

No.4 -- Iglosi elungileyo, imigca emihle kumphezulu.

Inkqubo yokucutshungulwa: ukupolisha kunye nokufudumala ukuqengqeleka kwe-2D okanye i-2B kunye ne-150 ~ 180 izinto ze-abrasive (JIS R6002).

HL -- Silver grey kunye nemivimbo yeenwele.

Itekhnoloji yokucubungula: Iimveliso ze-2D okanye iimveliso ze-2B ezinobunzima obufanelekileyo bezinto ezityhutyhayo zokupholisa umphezulu yinkozo eqhubekayo.

I-MIRRO--Ekhethekileyo.

Itekhnoloji yokucubungula: Iimveliso ze-2D okanye iimveliso ze-2B ezine-granularity efanelekileyo yezinto zokugaya ukugaya kunye nokupholisa kwisiphumo sesibuko.